Txron carbon steel screw details

Carbon steel refers to the carbon content of less than 2%, and contains a small amount of silicon Si, manganese Mn, phosphorus P, sulfur S, oxygen O and other impurity elements of iron-carbon alloy, because of its high hardness, strong pressure resistance, strong fatigue resistance, easy processing, superior mechanical properties and other characteristics, often used in the production of building fasteners, to meet the application needs of various construction projects. Yingfeng Txron carbon steel screws have the above mentioned advantages and more "personality", so it is favored by customers.

Txron carbon steel screws include: carbon steel hexagonal screws, carbon steel internal screw, carbon steel cross slot screws

Carbon steel hexagon screw

Head type: hexagonal washer, hexagonal flange

Thread: 10, 12, 14, 16, 20, 22, 24TY-B

Length: 20-240mm

Category: Stitching nails, structural nails, self-tapping nails, blasting nails, limiting nails, waterproof nails

Surface treatment: plating, C2, C3, C4, C4+ (coating)

(as shown below:)

Carbon steel internal plum screws

Carbon steel internal plum screws

Head type: T30 pan head

Thread: 14, 24TY-B

Drill tail: 2#, 3#, 4#, 5#

Length: 20-240mm

Category: Stitching nails, structural nails, waterproof nails, limiting nails

Surface treatment: plating, C2, C3, C4 (coating)

(as shown below:)

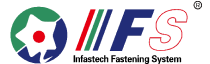

Carbon steel cross grooved screws

Head type: flat head, countersunk head, pan head

Thread: 14, 16, 20, 22, 24TY-B

Drill tail: 2#, 3#, 4#, 5#

Length: 16-200mm

Category: Structural nails

Surface treatment: plating, C2, C3, C4 (coating)

(as shown below)

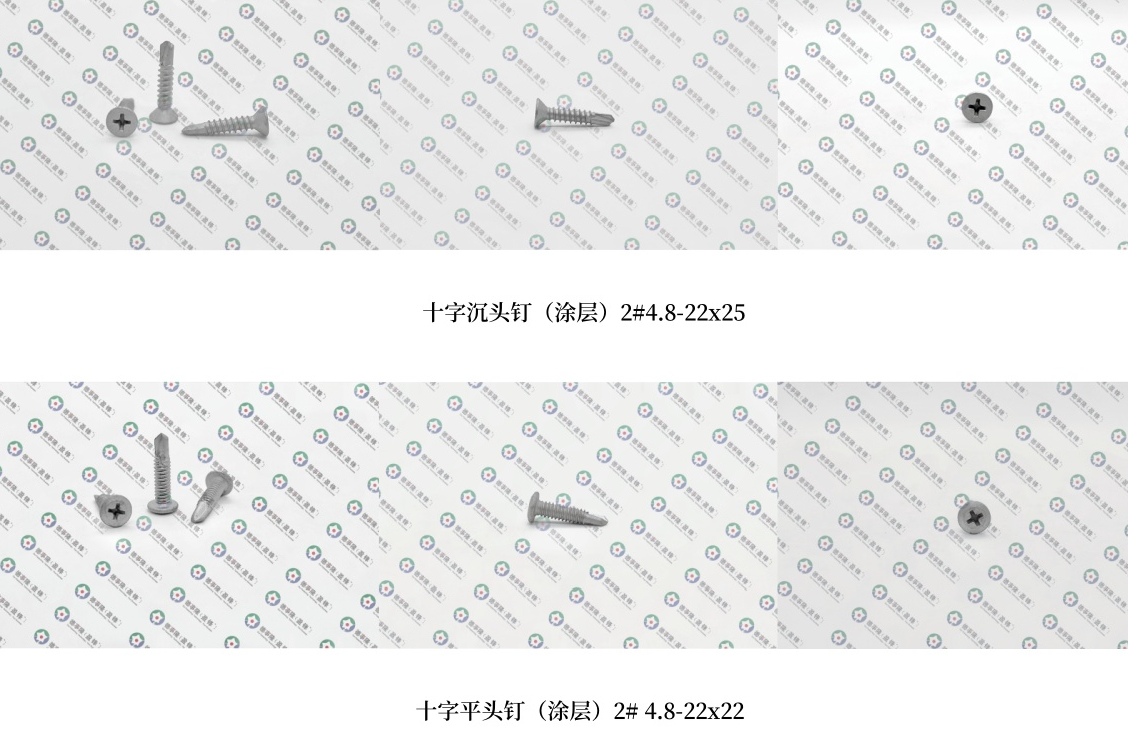

The following pictures show the common head type (Figure 1), groove type (Figure 2) and drill tail type (Figure 3, Figure 4) of Txron carbon steel screws, which can be customized according to specific requirements.

The quality of the product depends on the fineness of the processing process of the product, and then look at what is special about the processing process of Yingfeng Txron carbon steel screws.

1. Carburizing heat treatment

The carbon steel screw after carburizing heat treatment can remove the residual stress and increase the strength and toughness.

2. Scada coating is used on the surface

Txron screws are usually galvanized, coated and other surface treatment methods;

Txron Sgarda coating can cure zinc layer at room temperature without affecting fastener performance;

Meet the EU RoHS environmental standards, free of heavy metals lead (Pb), cadmium (Cd), mercury (Hg), and hexavalent chromium (Cr6+) and other harmful substances;

The anticorrosion grade reaches the Australian standard C4 level.

3.1500H high salt spray + acid rain test

Salt spray test 1500H and sulfur dioxide gas corrosion test (acid rain test) 25 cycles to ensure that our screws have high corrosion resistance and long service life;

Has obtained the third party SGS international certification.

Room temperature treatment, no high temperature tempering, screw strength does not decrease;

24H/48H hydrogen embrittleness test to ensure that our screws will not break easily.